As part of a recent renewal and rehabilitation project for the Czech water company JVS, AVK VOD-KA supplied a range of products, including AVK Premium 100 gate valves.

The water company Jihocesky Vodarensky Svaz (JVS) supplies approximately 16 million m³ of water annually to the supply area having 380,000 residents across 173 towns and municipalities. The water supply pipeline extends over 556 km and serves an area of 6,300 km².

In 2023, JVS renewed four valve chambers that had been regularly flooded. Existing gate valves often not functioning were replaced with DN400 AVK Premium 100 gate valves, along with telescopic extension spindles with break zone. They chose this solution due to the requirement for maximum quality and reliable operation, even in harsh environments and under the most demanding conditions.

AVK Premium 100 valves have an additional 1.5 mm protective PUR coating applied over an exceptionally thick layer of epoxy and therefore do not require additional external added insulation. This superior protection also results in time savings for the installation company on-site.

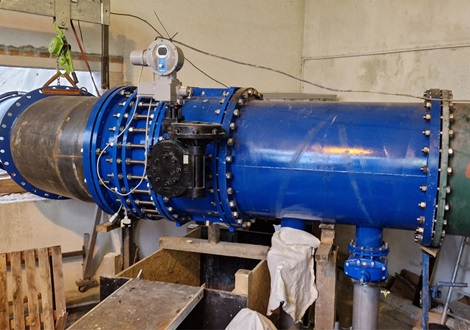

The image below shows a comparison of the original, replaced valve and the AVK Premium 100 gate valve from the installation site.

In 2023, JVS renewed four valve chambers that had been regularly flooded. Existing gate valves often not functioning were replaced with DN400 AVK Premium 100 gate valves, along with telescopic extension spindles with break zone. They chose this solution due to the requirement for maximum quality and reliable operation, even in harsh environments and under the most demanding conditions.

AVK Premium 100 valves have an additional 1.5 mm protective PUR coating applied over an exceptionally thick layer of epoxy and therefore do not require additional external added insulation. This superior protection also results in time savings for the installation company on-site.

The image below shows a comparison of the original, replaced valve and the AVK Premium 100 gate valve from the installation site.

Restoration of the raw water supply pipeline from the reservoir to the water treatment plant

The restoration of an almost seven kilometers long raw water supply pipeline began in 2023. The new DN1200 steel pipeline will run parallel to the existing DN1400 pipeline, which has been in operation for 42 years since the water treatment plant was commissioned.The project also includes an 82 m long DN1000 pipeline running under the Malše River, constructed using pressure drilling technology, three reinforced concrete chambers and additional structures.

AVK double eccentric butterfly valves are installed on the pipeline. The fixated disc prevents fluttering, extending service life and easing operation. The disc seal is made of AVK's own rubber compound featuring an excellent compression set and thus ability to regain its original shape.

In addition to butterfly valves, AVK VOD-KA also supplied control valves, and the chambers are equipped with AVK air valves, ensuring the necessary air capacity for filling or draining the pipeline, as well as operational aeration and deaeration. AVK air valves have a large orifice, allowing high-capacity airflow and significantly reduces the risk of clogging by debris. The air valves feature a patented rolling seal system that is sensitive to even small pressure variations.

AVK products supplied to the projects

Premium 100 gate valves DN50-400, 14 pcs.

Telescopic extension spindle with break zone, 14 pcs.

Double eccentric butterfly valves DN500-1000, 4 pcs.

Combination air valves, 6 pcs.